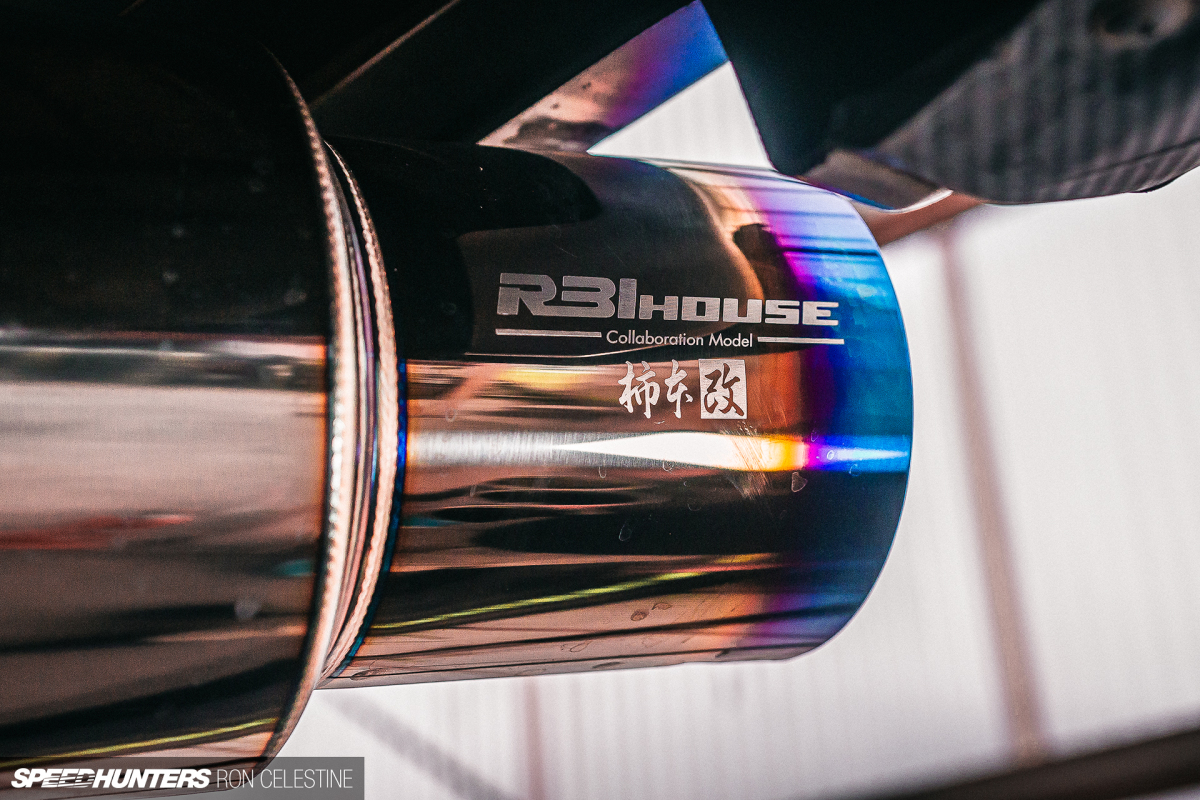

A Promise Kept & A World First For Project Rough

Vincent Lombardi, who many regard as the greatest American football coach of all time, once famously said: ‘Perfection is not attainable, but if we chase perfection we can catch excellence’.

When was the last time you worked on a project and nothing but absolute perfection would do? Not because if it wasn’t absolutely perfect lives would be at risk or you would somehow lose your job, but simply because it was a true passion project.

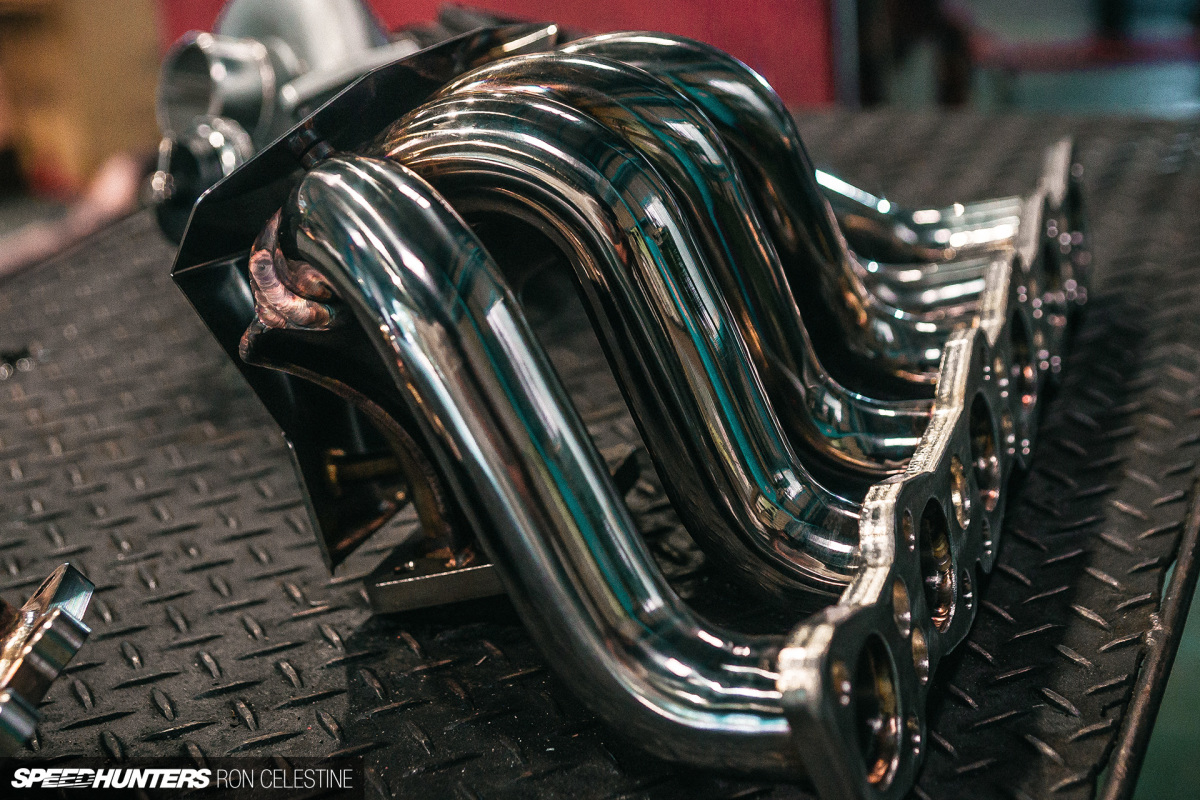

When Shibata-san at R31 House originally set out to create his takoashi manifold (AKA octopus header) for the Nissan RB20 – and then when he decided to create a version for the RB25 and fit the second set in existence on Project Rough to fulfil a promise – perfection was at the top of his mind. It just took 25 years to get to this point. Let me explain…

After graduating from Kanazawa Institute of Technology, Shibata-san met two new friends when he entered Central Japan Automotive Junior College. Both owned R31 Nissan Skylines, one being an Autech version and the other a rare GTS-R variant. Shibata-san himself owned an R31 Skyline GTS-X.

“The Autech acceleration was on a different level to my GTS-X, and the sound of the GTS-R was sublime. I wanted to make my GTS-X accelerate like an Autech, but sound like a GTS-R.”

Looking into the GTS-R’s engine bay, the tuned turbo manifold stood out to Shibata-san as the source of that brilliant sound.

He could have tried to get his hands on a genuine manifold to see if it did the trick, but that’s not so easy when only 823 GTS-Rs were ever built. Shibata-san also thought that would be boring; it would be far more rewarding if he could make one himself.

Over the next 10 years, Shibata-san experimented with different configurations and worked with shops all over Japan to try and build his ultimate R31 manifold. In that time, just five different iterations were created. All increased power – a nice bonus – but the sound wasn’t quite right. It was close, but not close enough.

However, the Skyline owners who were testing the prototype R31 House takoashi manifolds were happy, so why press on?

Simple: Shibata-san felt as though he hadn’t tried everything in order to achieve the ‘perfect’ sound. In his mind, even if it sacrificed a little performance, pushing on would ultimately be worth it.

The eureka moment came when he realized that some form of in-manifold resonator was required. Without delay, Shibata-san begun asking around to see if it could be done.

At first he tried the local Gifu region, but to no avail. Then he expanded his search to all over Japan, but the answer was always the same: it can’t be done. Shibata-san refused to take no for an answer, so a worldwide quest followed and eight years later he found a company willing to take on the challenge.

This company was based in Taiwan, and their expertise was supercar exhaust systems. It all sounded great until Shibata-san learned that only one person did the welding, and due to the complex nature of this project and all the other work they had lined up, it would take an additional two years to complete the second version of the R31 House takoashi manifold.

For those playing along at home, we’re now up to 20 years.

The Next Piece Of The Puzzle – Boost

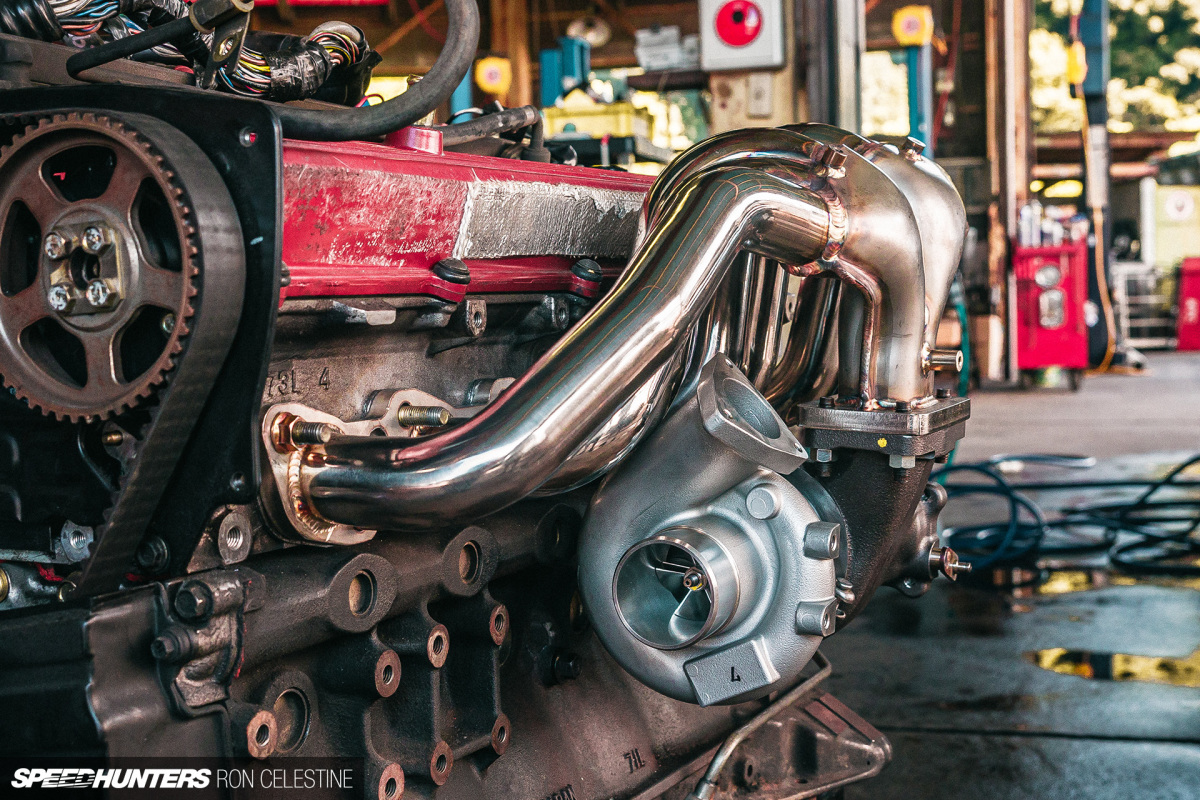

Believe it or not, the turbocharger also plays a small role in creating the perfect sound, Shibata-san already knew this. The GTS-R came with a larger Garrett turbocharger than the lower-spec models with ceramic turbos, meaning it could expel more air out the exhaust.

Shibata-san wanted to see if he could get away with using the stock turbocharger on the GTS-X, thus another experiment began. A variety of brands and turbo frame sizes were tested in order to see what would best help with the sound, and add a bit of power.

Since Shibata-san had a good relationship with HKS, he zeroed in on the HKS GT25 series. The GT2533 was too big for the RB20DET and the GT2510 was too small. On paper the GT2530 was almost perfect, but the throttle response wasn’t where Shibata-san needed it to be. What he wanted was a goldilocks size, something between the GT2510 and GT2530.

The only problem was that size didn’t exist, and even with Shibata-san’s strong relationship with HKS, they were simply too busy to bring his dream R31 turbocharger to life.

The stars aligned though when his friend, Michiya Sakumasu, retired from HKS after 30 years of service building turbos, and created his own company, Boost Magic. Sakumasu-san asked Shibata-san, if he was to make an original turbo for him, what would it be.

As a result, the GT2525, or as more affectionately called at R31 House, the niko niko (smile) turbocharger was born.

Note: 2525 in Japanese is ni go ni go, which is close enough niko niko, a silly joke according to Shibata-san.

Based on the GT2530 turbocharger, the GT2525’s smaller size aims to keep things as lineal as possible which, surprise surprise, gives the driver more control over the sound that comes screaming out of the engine’s exhaust.

The combination of takoashi manifold, the GT2525 turbocharger and a supporting tune can lift RB20DET power output to a respectable 300whp. With the RB25DET, a little over 350whp can be achieved.

The Remaining Five Years

In the beginning I said to get to the point where we are today has been a total of 25 years in the making. I counted up to 20, so what about the other five years?

The promise that Shibata made to me at Tokyo Auto Salon some years back, was that he wanted to install the takoashi manifold on Project Rough. Simply, he needed to make sure it would fit on a RB25 as it had never been done before. Essentially, my car was going to be the guinea pig for the idea.

Shibata-san quickly realized though, that the R31 has more available engine bay real estate than its newer siblings. As a result, the manifold’s length would need to be shortened by 30mm to fit.

A simple idea snowballed rather quickly. Throw in a global pandemic and here we are now – inside a discreet new building that Shibata-san calls his race shop.

Before we could get to the really exciting bits, we still needed to head to the parts yard and liberate the high pressure power steering line from a wrecked ER34 – the reason I headed down to R31 House in the first place. Removing the line is a million times easier when you’ve got a forklift on hand!

With the brand-new-to-me pressure line out, R31 House mechanic Nabe-san wasted no time getting Project Rough up in the air to see what else might need replacing.

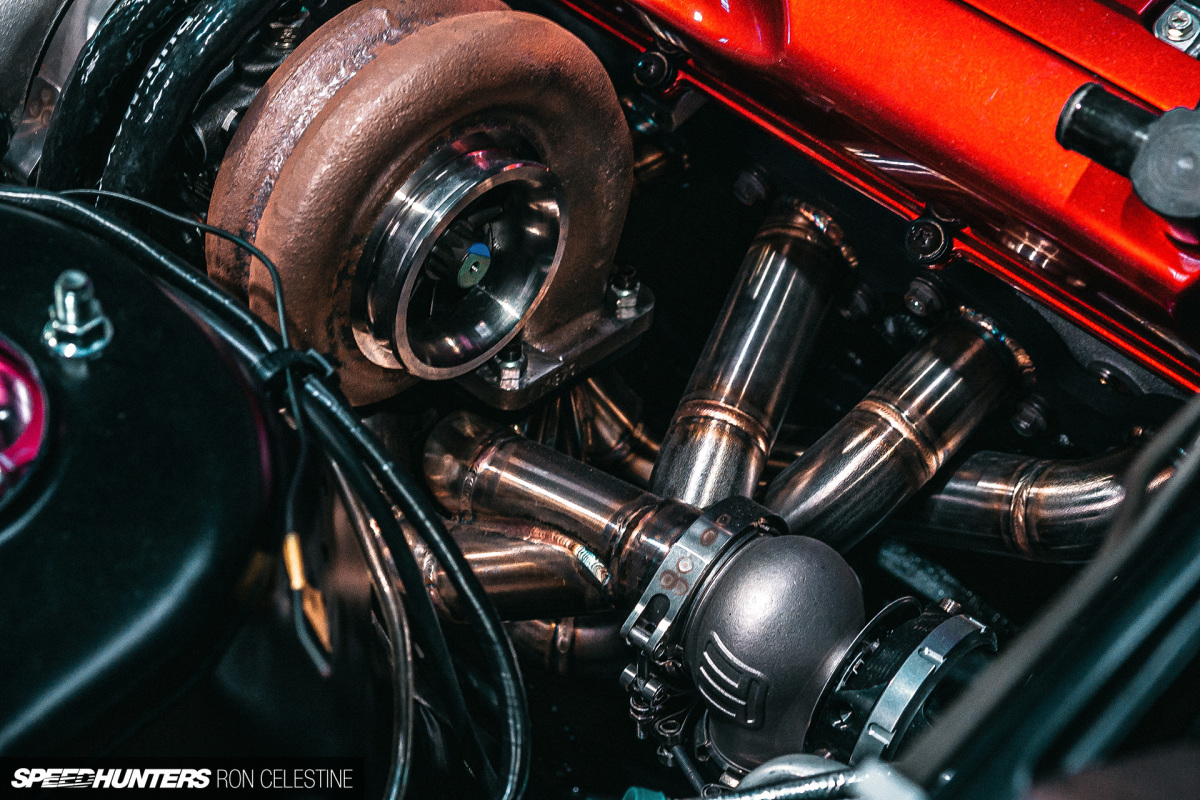

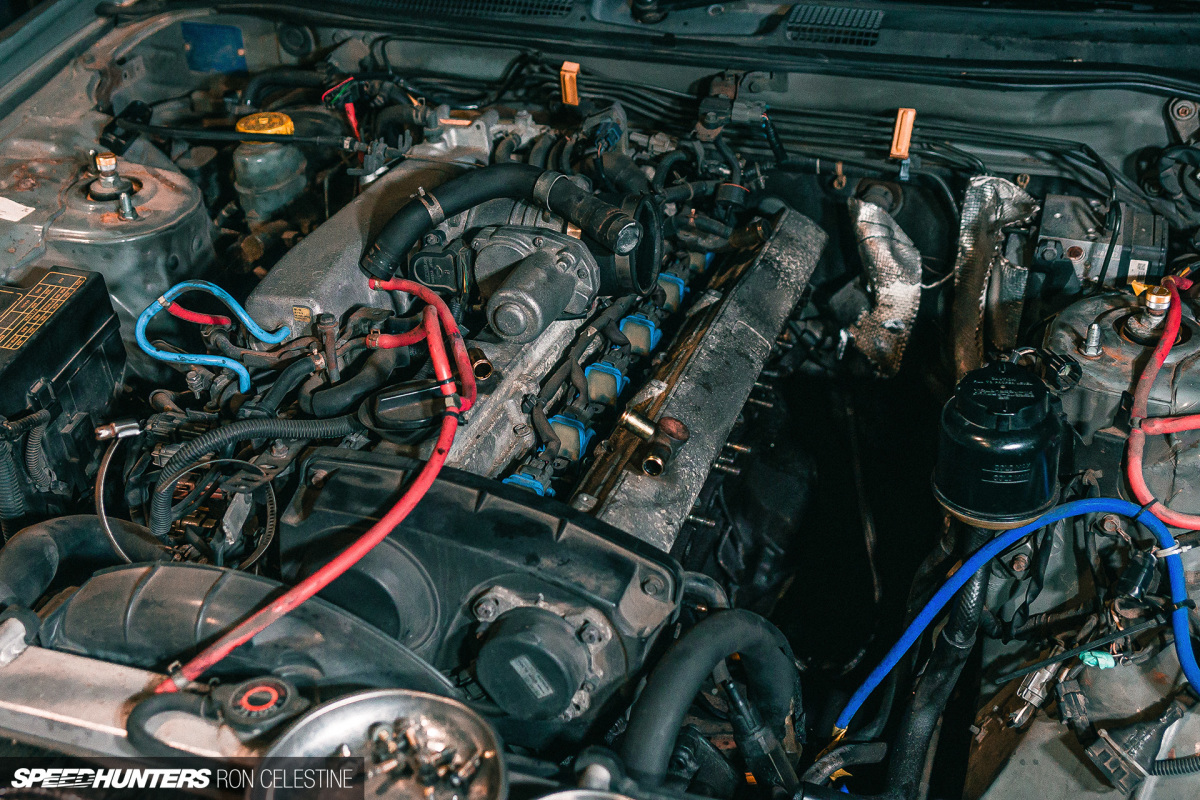

With a game plan in place, Nabe-san and fellow mechanic Akaboro-san set about removing the entire exhaust system, old turbo and manifold.

Typically, Project Rough takes great joy in torturing challenging me with seized bolts. However, it gladly released the old turbo without fuss.

The manifold was a little more stubborn, but eventually was freed from the side of the head.

Before I really knew it, the R31 House’s prototype RB25 takoashi and new GT2525 turbo combination was being sized up for its new home.

And then actually fitted. But that’s where this story ends.

No, this isn’t another cliffhanger (well, it kind of is by default), but as of writing this, I genuinely don’t know how the complete install went. Being the first R34 to receive this upgrade, custom fabrication was going to be required, and thus I left Project Rough at R31 House and returned home.

Shibata-san mentioned installing a few more parts to ensure my Skyline makes the perfect sound, but only he and a few others around him actually know what that perfect sound is. He has purposely not uploaded any footage as he wants me to share it with the world, so my first time hearing it will be when I come back to pick Project Rough up.

Stay tuned for the finale.

Ron Celestine

Instagram: celestinephotography

www.labcuriosity.com