Built-in CAM Packs a Punch for CNC Machining

Producing Engineering: What are the most up-to-date complex tendencies in CAD/CAM software program enhancement?

Marc Bissell: Some of the biggest technological innovation tendencies are in intelligent producing and Marketplace 4. initiatives. These encompass automation and digital transformation, providing companies systems wanted to enable them be considerably much more effective.

Today’s technologies also make doing work remotely extra feasible than at any time, and the COVID-19 pandemic is hastening both equally the demand for automation and rising the require for sensible methods in remote manufacturing.

Applying automation and going to digital producing can be challenging and has some certain problems. A lot of producing corporations may see it as one thing that will come with a massive rate tag or necessitates a prolonged, sophisticated implementation. Nonetheless, manufacturing companies can take measures to little by little integrate extra automation into their machine stores and quickly see the positive aspects of employing some of today’s superior systems.

CAD/CAM application that is completely integrated—such as SOLIDWORKS, SOLIDWORKS CAM and CAMWorks—provides quite a few positive aspects. Initially, designers and the programmers use the similar software program environment to design and style the element, method machinable attributes, generate the toolpaths and crank out the NC code. With an integrated process, the CAD and CAM styles develop into a single. Teams can consider parts all the way from conceptual style to a closing solution in the exact same program interface. All the CAD and CAM data is saved in a one file, so there is no require to manage different CAD and CAM files and no details translation challenges. There is also no danger in machining an obsolete section for the reason that the toolpaths are thoroughly associative to the design design and they update automatically when a style and design or engineering transform occurs.

Another pattern is automation equipment, this kind of as attribute-based mostly programming and expertise-primarily based machining, which have several added benefits around functions-based mostly CAD/CAM program. The databases of machining know-how in the CAD/CAM software package will choose the appropriate resources (from a device crib that matches the shop’s out there resources), calculate the optimal feed/velocity rates, utilize the acceptable roughing and ending toolpaths, and crank out the NC code.

Using this a stage even further, with the SOLIDWORKS CAM and CAMWorks Technologies Databases (TechDB), programmers can edit any of the instantly picked selections and help save them to a enterprise-owned attribute and strategy library. This will allow producers to seize their best techniques and reuse them routinely. This assists standardize and automate tooling and CNC programming procedures.

ME: What’s new with your most recent CAD/CAM program?

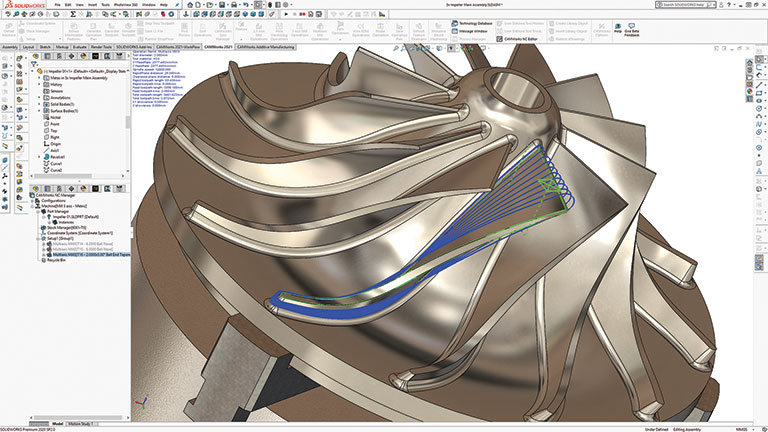

Bissell: HCL recently unveiled CAMWorks ShopFloor, which provides strong CAD/CAM operation to machinists without the need of the need to have a full CAD/CAM system on the shop floor. When the CNC programmer has done the aspect programming in SOLIDWORKS CAM or CAMWorks, they publish the ShopFloor file for the machinist. All the CAD/CAM facts vital to manufacture the element is bundled in a single digital file, allowing businesses to move further than the use of 2D drawings or static PDF information.

When the machinist opens the file in the ShopFloor software, they have accessibility to digital setup sheets, tool lists and the G-code system to support in the set up of the CNC device. With the comprehensive CAD viewer bundled, they can screen the native style design with GD&T dimensional information and annotations of the 3D portion design. They can rotate, zoom, pan and portion watch the product. They can also choose linear, radial, angular, and region measurements. In addition, the MBD and PMI information can be considered, searched and filtered.

Toolpath simulation choices give the machinist the potential to do a step-as a result of simulation and review each and every procedure at the equipment, devoid of the have to have to wander the device by every chopping phase or dry-working the program. A CNC Editor driven by Cimco is also involved, which permits the machinist to look at and edit G-code, renew the CNC software to perspective the affect of the edits made, again-plot straight from the G-code, make any closing changes, and mail the system to the CNC equipment.

ME: How are users applying new CAD/CAM applications and procedures in manufacturing?

Bissell: Various of our shoppers are employing integrated CAD/CAM although doing work remotely. They use SOLIDWORKS for layout, CAMWorks or SOLIDWORKS CAM for remote programming, with CAMWorks Virtual Equipment for simulation and CAMWorks ShopFloor on the shop flooring to assure that communication in between engineering and machining is in sync. Also, several other prospects are embracing and employing the automation accessible in SOLIDWORKS and CAMWorks, together with API apps, to automate the CNC programming procedure. This has permitted them to mature their business enterprise and continue to be effective by means of the recent COVID-19 pandemic.

ME: What impact are some of the more recent additive resources possessing these days in CAD/CAM?

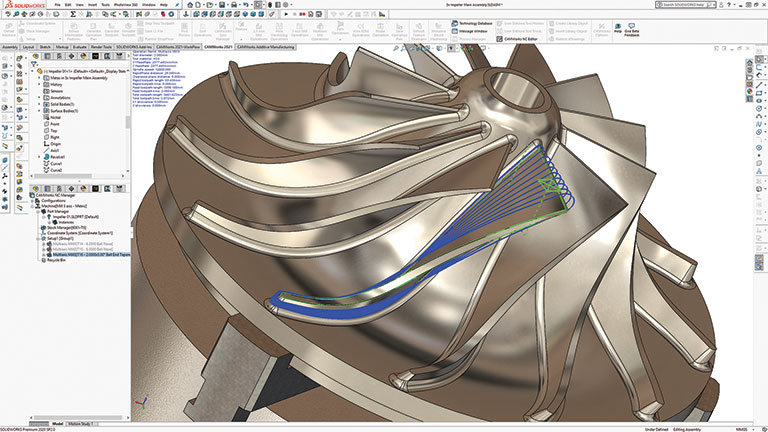

Bissell: As the demand from customers for additive manufacturing has grown, demand to support it using CAD/CAM has also grown. As a result, HCL has created CAMWorks Additive Producing, run by Materialise engineering, which is the very first (and only) additive-subtractive remedy accessible for SOLIDWORKS. This allows end users to put together products for 3D metal printers within SOLIDWORKS. The 3D printer model is then utilised as inventory, and CAMWorks generates the CNC subtractive machining functions and toolpaths desired to get rid of the develop supports and machine other consumer-defined spots of the component, all within SOLIDWORKS. The layout, additive and subtractive details are all saved in a one file, creating it totally associative with the SOLIDWORKS design. Structure improvements are up-to-date in the additive and subtractive programming.

ME: Are CAD/CAM devices getting much easier to use?

Bissell: Indeed, they are unquestionably getting to be less complicated to use. The systems described earlier mentioned, including element-dependent programming, automatic function recognition and information-primarily based machining aid brands use automation to streamline style-to-manufacture processes, boost productivity and produce greater-excellent sections. Technological know-how is ever improving upon, which usually means manufacturers are pressured to supply additional, a lot quicker. Keeping competitive in today’s market involves adoption of state-of-the-art CAD/CAM technologies. CAMWorks automation is producing CAD/CAM a lot easier to use, notably for new programmers who can profit from many years of knowledge and ideal tactics from the top programmers and machinists, captured in the TechDB.

ME: Toolpath simulation is also essential to rushing and automating metalcutting productiveness. What are some of the critical traits in toolpath and equipment simulation?

Bissell: The essential developments concentrate on significant enhancements in equally functionality and accuracy, digital twin comparison, application optimization, and device recognition or recognition. Exact, legitimate G-code simulation is necessary to avoid machine collisions and broken instruments. Many thanks to effectiveness advancements in simulation, programmers get close to-instantaneous suggestions and simulation that can be utilised interactively to generate every single operation.

For example, fairly than creating an operation and working simulation right after the simple fact, only to uncover a machining parameter requires to be changed, CAMWorks makes it possible for the programmer to run both of those toolpath and stage-by way of simulation on-the-fly as they generate an operation, modify machining parameters, and see the final result just before accepting the operation. Also, working with CAMWorks’ latest probing technology, as the consumer makes probing functions the toolpaths are immediately displayed, and when the parameters are altered toolpaths quickly update. Likely ahead, machine simulation will come to be interactive relatively than after-the-reality, and will go up to turn into aspect of the CAM programming workflow.

New TrendMiner 2021.R1 Software package Introduced

Program AG’s TrendMiner, Hasselt, Belgium, has unveiled TrendMiner 2021.R1 computer software, which allows bridge the information hole among engineers and details scientists. This most current release brings a new operation of notebook integration, which aids end users obtain each facts dashboards and code-based mostly details investigation.

TrendMiner permits operational specialists in system industries to assess, check, and forecast operational efficiency applying sensor-created time-collection data. TrendMiner’s goal is to empower engineers with analytics for enhancing operational excellence without having relying on data scientists.

In the 2021.R1 release, consumers can soar from on the lookout at facts in a TrendMiner view to operating with it in a code-primarily based information science atmosphere.

With their details science libraries of option (e.g., Pandas, NumPy, SciPy, SciKit-Discover), engineers can produce and run customized scripts for superior statistical analyses and use AutoML abilities to establish equipment learning products for anomaly detection. They can also operationalize the resulting notebook visualizations (also established with libraries of their preference these types of as Matplotlib, Plotly, Seaborn) as dashboard tiles in TrendMiner DashHub.

ModuleWorks Adds New 2021 Parts

CAD/CAM computer software components developer ModuleWorks GmbH, Aachen, Germany, has produced its 2020.12 CAD/CAM computer software factors, like rotary machining for conical workpieces adaptive turning with non-spherical inserts roll-in moves good measuring capabilities for subtractive and additive simulation and person-described ending curves.

Elaborate workpiece geometries, these as those people identified in injection molds and conical screw compressors, pose a special obstacle for rotary machining. The latest ModuleWorks rotary machining elements align the software perpendicular to the cone-shaped floor to optimize the toolpath sample for conical shapes. This minimizes the quantity of depth steps for roughing, gets rid of step-downs for ending and minimizes the amount of linking actions to increase cutting ailments and pace up the generation of conical pieces.

ModuleWorks Smart Evaluate is a touch-monitor tool that allows customers to interactively measure distances, radiuses, angles, clearances and depths on shares and meshes. New functions have been additional for the ModuleWorks 2020.12 release that permit users to measure the distance among two arcs and to evaluate capabilities on the workpiece although the turning simulation is working. For lathe functions, customers can now evaluate the stock radius the edge angle the floor radius the stock internal depth right after drilling or boring operations and wall distances after grooving operations.

Doosan Chooses ModuleWorks Simulation

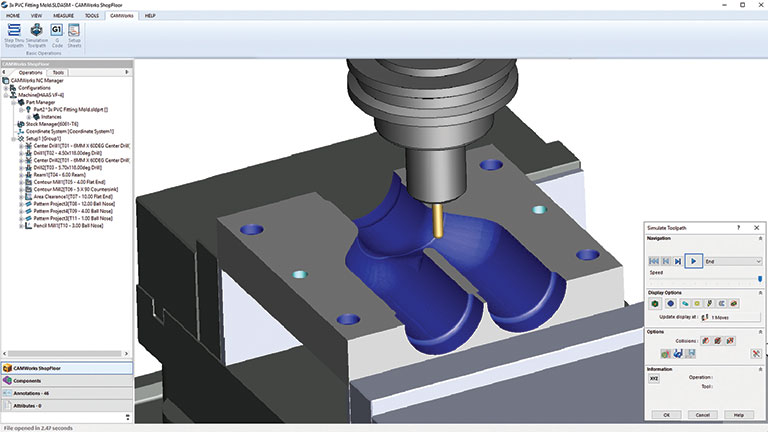

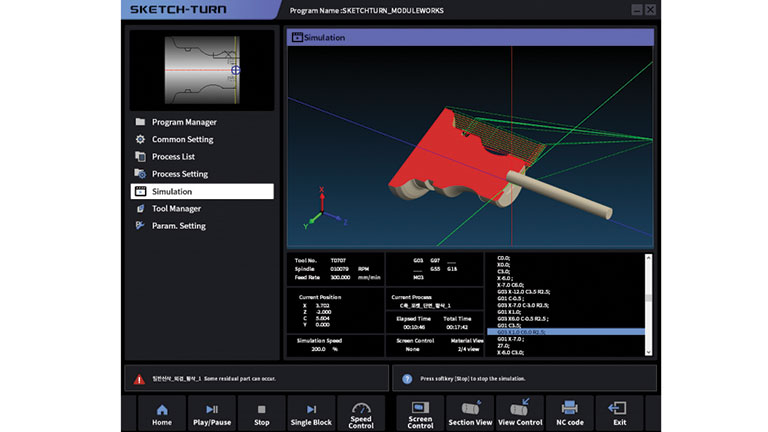

Doosan Device Instruments, Pine Brook, N.J., has integrated the ModuleWorks chopping simulation technology into its Sketch Change product. The ModuleWorks software program replaces Doosan’s former cutting simulation engine and is portion of Doosan’s approach to improve the availability and effectiveness of machining info on the store floor.

Sketch Convert is an automatic NC programming surroundings that helps operators in making and editing machining courses for Doosan turning centers. The built-in ModuleWorks simulation computer software boosts Sketch Convert with stock removing verification for mill, change and put together mill-flip apps. The graphic simulation and NC method are shown upcoming to each and every other on the Sketch Transform interface to empower operators to detect challenges and edit the G-code.

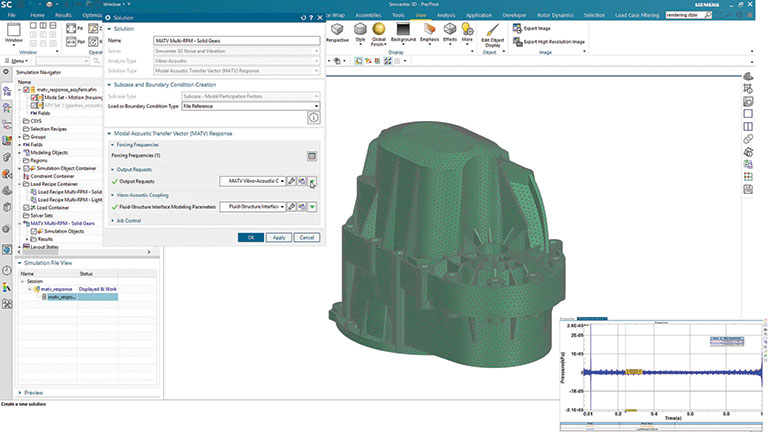

Siemens Provides Simcenter 3D 2021

Siemens Electronic Industries Application, Plano, Texas, has unveiled its Simcenter 3D software package, aspect of the company’s portfolio of simulation and test methods. In the 2021 launch, Simcenter 3D improves its unified and shared engineering platform for all simulation disciplines.

With new enhancements to the AI-driven consumer experience, new simulation sorts as perfectly as refinements in precision and enhanced effectiveness velocity, Simcenter 3D 2021 can assistance corporations recognize the functionality of their patterns early in the improvement process.

In a lot of purposes, solution innovation consists of the engineering of the superior content utilized in them, which is why new elements are currently being launched at unparalleled pace. Cracking is an crucial thought for superior products nonetheless micro and meso cracking in innovative products is tough to design with the finite component strategy. The Simcenter 3D computer software now involves complete representative volume aspect (RVE) separation and 2D and 3D automated insertion of cracks or cohesive zones in components. Macro and microstructural products now allow for total mesh separation for a crack to propagate absolutely via a product.

PTC Finalizes Arena Methods Acquisition

PTC, Boston, has finished its acquisition of Arena Solutions Inc., Foster Metropolis, Calif., the developer of Application-as-a-Service (SaaS) merchandise lifecycle management (PLM) solutions. The addition of Arena Options bolsters PTC’s placement with pure SaaS answers in addition to the company’s before 2019 acquisition of Onshape.

In December, PTC agreed to invest in Arena for $715 million in hard cash. Arena Options finished calendar calendar year 2020 with close to $50 million in annualized recurring income, reflecting double-digit development around 2019.

With the closing of the Arena Alternatives acquisition, PTC expanded its SaaS company unit, which now features Arena, Onshape, and PTC’s Vuforia augmented actuality technological know-how. The expanded organization unit will be led by very long-time PTC Global Gross sales Chief Mike DiTullio, reporting instantly to PTC’s CEO Jim Heppelmann. Jamie Pappas, a 25-calendar year PTC profits veteran, has been elevated to thrive DiTullio as head of world wide sales.

PTC proceeds to be expecting that the transaction will be neutral to PTC’s fiscal 12 months 2021 funds movement from functions target of $365 million and cost-free hard cash circulation target of $340 million (which displays the deduction of close to $25 million of money expenditures from dollars flow from functions) and accretive to fiscal yr 2022 and beyond.

Siemens Provides Company-Broad Good quality to Teamcenter

Siemens Digital Industries Program, Plano, Texas, produced Teamcenter Top quality application. This new suite of options offers a closed-loop solution for high quality administration, from style to the shop floor and back once more. Teamcenter Top quality allows maintain products growth, excellent planning and constant advancement processes in synchronization to help maximize the benefit of adjust and configuration administration capabilities on the Teamcenter system.

The new extension to the Teamcenter portfolio lets engineers to set excellent demands early in the style and design approach and establish the parameters demanded to ensure the merchandise produced will meet up with high-quality benchmarks. Teamcenter Excellent is accessed by way of a internet interface and includes AI-enabled person steering with Teamcenter Assistant features.

Software program Update is edited by Contributing Editor Patrick Waurzyniak make contact with him at [email protected]